Schweissvorrichtungen,Kompaktiervorrichtung

PRODUKTE > WIDERSTANDSSCHWEISSEN

Kompaktieren mit WELD-TECH

Kompaktieren und Vorverdichten für das anschließende aufspleißsichere weiterverarbeiten von Kupferlitzen (Cu-Litzen) aller Art.

Kundenvorteile:

- Kein aufspleißen der Litze mehr, Sie können Ihre Litzen als Schüttgut verwenden.

- Kostenersparniss es muß kein ein Zusatzmaterial (Crimp, Aderendhülse) verwendet werden.

- Investitions Einsparung kein teures Equipment muß geordert werden.

- Hohe Präzision und Zuverlässigkeit.

- Wird in der Automobiltechnik eingesetzt.

- Funktionelle Präzisionsarbeit.

- Auf Anforderung können wir Ihre Litze Gasdicht verdichten.

- Universell von 0,25 mm bis 2 und von 2 - 16 mm².

- Kann an jede vorhandene Widerstandsschweißmaschine angebaut werden werden.

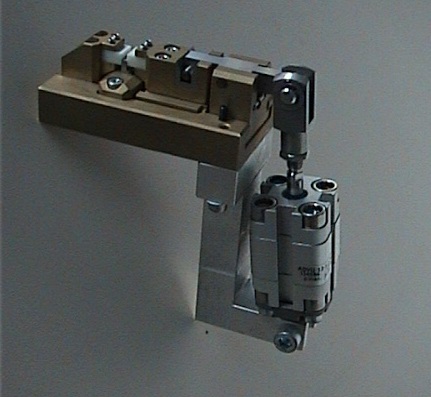

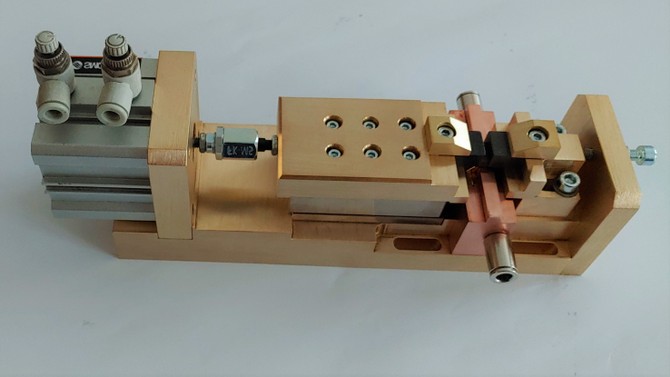

Weld-Tech Kompaktiervorrichtung WTKV 0,5-2,5

Pneumatische Mirco Kompaktiervorrichtung für Kabelquerschnitte 0,5mm²-2,5mm²

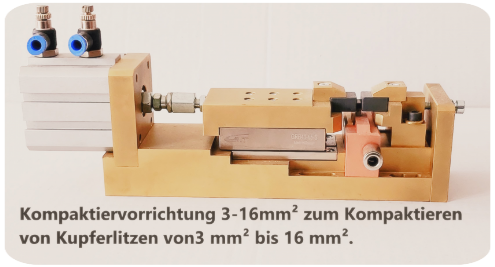

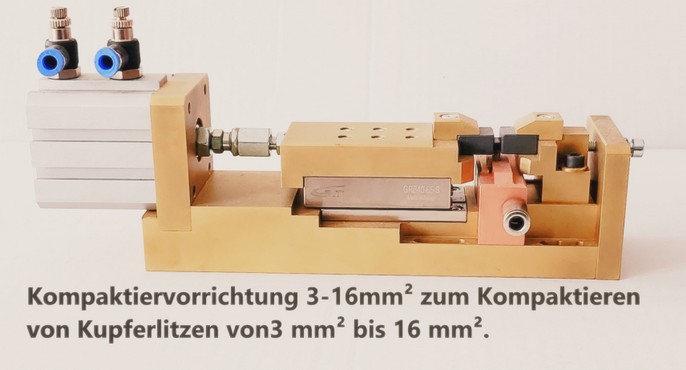

Weld-Tech Kompaktiervorrichtung WTKV2Z16R

Pneumatische Kompaktiervorrichtung für Kabelquerschnitte 2,5mm²-16mm²

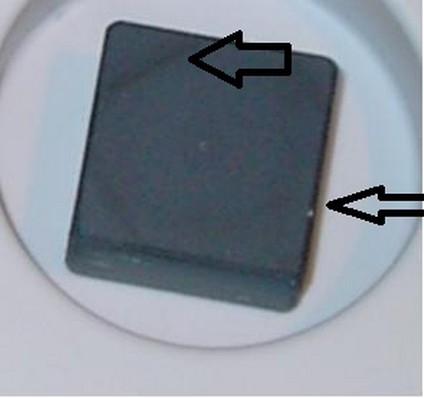

Detailansicht eines Kompaktiervorganges

Kompaktiervorrichtung mit eingelegter Litze.

Klemmbacken und Elektroden während des Kompaktiervorganges

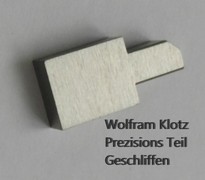

Zubehör für die Kompaktiertechnik

Standardkeramikbacken und Spezialkeramikfür die Widerstandschweißtechnik insbesondere für die Litzenkompaktiertechnik.Anfertigung nach individuell nach Ihren Vorgaben und Anforderungen.Die Spezialeramik ist sehr hoch Hitzeschockfest und Druckfes gut geeignet zum Widerstandskomkpaktierschweissen.Mit höchster Wärmeschock und Druckfestigkeit weist diese Art der Keramik eine hohe Standmenge und geringsten Verschleiß auf.Verschiedene Maße in der Ausführung:Roh (ungeschliffen) oder Fertig (geschliffen) zum Tel auf Lager.Verschleißtest einer Hochfesten KompaktierkeramikSie sehen hier eine Keramikbacke mit den Maßen 14 x14 x 9 mm nach 1 000 000 Kompaktierungen mit geringsten Verschleißanzeichen.Farblich sind Abweichungen und leichte Glanzstellen zu sehen, aber die Mechanische-, und Wärmefestigkeit waren noch sehr gut.

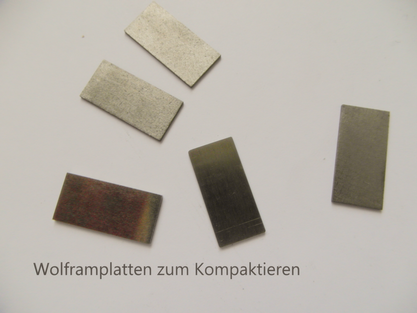

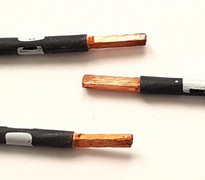

Standardkompaktierelektroden

Standardkompaktierelektroden aus den Materialien Wolfram rein,Wolframlanthan,Molybdän und Titanzirkomolybdän.

Im Rondell sehen sie Kompaktiervorrichtungen und eine kleine Übersicht von Zubehör. Hochwärmefestes und Hochstoßfestes Keramik und Kompaktierelektroden.